coating sealants

A More Sophisticated, Well-Rounded Approach to Environmental Circuit Protection

When striving to protect delicate electronic circuits from the ravages of harsh environments, conflicting forces often seem to rule the day. Shielding a circuit board from an environment where chemical solvents will frequently be encountered, for example, may seem to require the use of epoxies or other permanent solutions that can shrug off such influences. In fact, though, efforts of that kind may prove to be short-sighted, as a circuit treated in such a way many therefore no longer permit repair when it might be needed.

Even in the toughest environments, then, it is often more flexible and subtler solutions that actually make the most sense. While the relatively crude approaches that prevailed for many years often seemed to solve at least one problem, they typically came with downsides that made them less than satisfactory, in the overall analysis. Today's options, on the other hand, often provide service in a much more holistically compelling way.

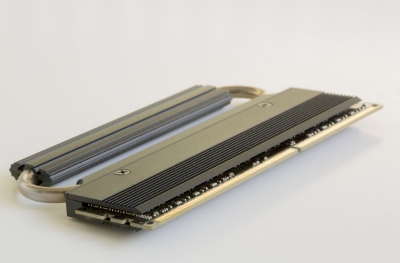

The Para Tech pvd coating that is often used to shield electronic components today, for example, uses a sophisticated approach to provide protection of a very well-rounded sort. Instead of employing the kind of thick, but impenetrable coating that was formerly the norm, the approach described at http://www.parylene.com/equipment.php is much more elegant, and that shows in the results that it produces.

That technique revolves around the application of dimeric parylene particles that are first suspended, within a vacuum, into gaseous form. The part to be treated is then introduced into a chamber flooded with that gas and nothing else, so that the utmost in purity of application can be guaranteed.

As the particles in the gas settle on the surfaces of the part, a coating of unparalleled regularity and coverage is produced. Because it is applied so precisely and thoroughly, the coating affords the utmost in protection, rivaling the thickest coatings of the traditional sort in this respect.

That precision of application, though, also means that the coating is relatively easy to remove by focused, intentional means. That means that parts treated in this way are just as amenable to later repair as those that are left unprotected, a truly valuable advantage.